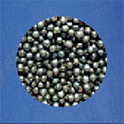

Steel grit is made from high carbon cast steel shot by crushing it into sand grains, and then tempering it into three hardnesses (GH, GL, GP) to suit different needs. The processed steel grit is screened into 10 grades that meet SAE standards to suit sandblasting needs.

Products of different sizes and hardness are used in different situations, such as rod engraving, granite cutting, etc.

Our steel grit adopts the production process of Japan's Shinto Company. The hardness, density and microstructure of the product are very uniform and consistent, and it also has good strength and durability. These characteristics make the product have good cleaning and shot blasting performance.

Steel grit is widely used in the pretreatment of steel workpieces before painting. In this process, the most commonly used method is a sandblasting room with a recycling device. The angular shape of the sand grains and the related hardness make it have a faster cleaning speed and can be effectively recycled.

Steel grit is also widely used in the sand cleaning process of castings. When the workpiece is too hot, sometimes the casting sand will be embedded in the casting, which exceeds the cleaning capacity of the steel shot. At this time, only steel grit can be used.

When the shot blasting equipment using steel shot cannot effectively clean the steel workpiece, steel grit can be used.

Applicable industrial scope

Aviation industry; Automobile industry; Sandblasting/painting companies; Consumer goods manufacturing; Container manufacturing/repair; Casting;

Granite/stone cutting; Shipbuilding and ship repair; Oil and gas pipelines; Plant maintenance and metal processing.

Applicable process scope

Surface pretreatment before spraying, casting sand removal, pipeline descaling, etc.