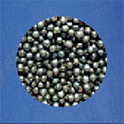

Sodium bicarbonate abrasive is a water-soluble green abrasive suitable for open sandblasting with strict requirements for low dust and waste emissions. At the same time, sodium bicarbonate abrasive can also replace those traditional chemical paint removers that pollute the environment and be used for the process of removing coatings from delicate workpieces. Sodium bicarbonate abrasive can be used as a dry sandblasting abrasive or when wet blasting with water added to the airflow. In wet blasting cleaning applications, more ideal results can be obtained by adding compounds such as detergents and rust inhibitors. In wet sandblasting, water flow can also play an auxiliary spraying effect. In this way, multiple factors act at the same time, and oil and other debris on the workpiece can be easily cleaned during one blasting process. When used for equipment maintenance purposes, sodium bicarbonate abrasive will not damage seals, bearings, shafts, pumps and other parts. At the same time, because it is soluble in water, the workpiece cleaning and dirt emissions can be minimized after sandblasting.

Sodium bicarbonate abrasive can also be used in flexible dry and wet sandblasting. Sodium bicarbonate can be used to remove paint/coating from flexible workpieces without damaging the inner layer, such as glass, plastic, wood, brick, brass, aluminum, concrete, etc. In the process of removing paint, the paint can even be removed layer by layer to ensure that the paint layer that does not need to be removed is intact.

Applicable industrial scope: aerospace/aviation, automobile, spray distribution, ocean-going ship repair, oil and gas pipelines, and factory maintenance, etc.

Applicable process scope: cleaning before machine maintenance; related processes of concrete/brick; paint removal of cars, trucks, locomotives, etc.; cleaning of metal containers for the food industry, etc.