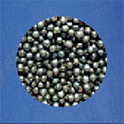

Emery is also called silicon carbide or refractory sand. Silicon carbide is made of raw materials such as quartz sand, petroleum coke (or coal coke), sawdust (salt is needed when producing green silicon carbide) and other raw materials through high-temperature smelting in a resistance furnace. At present, the silicon carbide produced industrially in my country is divided into black silicon carbide and green silicon carbide, both of which are hexagonal crystals with a specific gravity of 3.20-3.25 and a microhardness of 2840-3320kg/mm2.

Silicon carbide is an extremely hard and sharp hard abrasive. It is made by melting quartz and petroleum coke in an electric furnace at a high temperature of 2200℃. Its chemical properties are very stable, with high oxidation resistance, and it will not react with acid. It will only react with alkali at extremely high temperatures. As an abrasive, the hardness of silicon carbide is second only to diamond, cubic boron nitride and boron carbide.

Due to its extremely high hardness, silicon carbide can cut very quickly and can also be used to clean or etch the surface of harder workpieces, which are impossible for soft abrasives. Tungsten carbon alloy products can also be cleaned with silicon carbide.

Silicon carbide is harder and sharper than aluminum oxide, but it is also more brittle, so the breakage rate is higher during use.

Silicon carbide products are available in two types, G and B.

G is the purest silicon carbide for commercial applications and can be used in many occasions: such as sandblasting, glass engraving, manufacturing consolidation molds and coating molds, ceramic industry, etc. It is most suitable for surface treatment of non-ferrous materials such as carbide, optical glass and ceramics.

B is used for surface treatment processes that require fast cutting without leaving iron chips. It is also widely used in consolidation and coating mold manufacturing (such as sandpaper, oilstone and grinding wheel), refractory products and glass engraving.

Applicable industrial scope: aerospace industry, automotive industry, consumer product processing, casting/die casting, granite cutting, OEM distributors, semiconductor industry.

Applicable process scope: casting sand cleaning; surface spraying pretreatment; metal sandblasting and painting; aluminum, alloy and non-ferrous products deburring; mold cleaning; metal and crystal grinding and glass engraving.