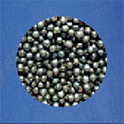

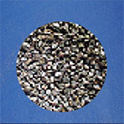

It is widely used in the sand cleaning and rust removal, polishing and surface strengthening of forgings, castings, heat treatment, steel plates in the manufacturing industries of machinery, automobiles, aircraft, motorcycles, railway locomotives, shipbuilding, containers, bridges, chemicals, etc. Cast iron sand is a sharp, hard, angular metal sand material, which is an ideal abrasive for extremely fast sandblasting cleaning of steel workpieces. Because it is very fragile, it will break into smaller particles after being hit, with the same shape and sharp and angular characteristics as the original sand particles. The result of this characteristic is ultra-high-speed cleaning and high productivity. Since the sand particles always maintain the same form after multiple hits, they can be used in processes that require constant processing effects. JZRTM is particularly suitable for compressed air sandblasting equipment that requires high productivity. Due to its low cost, cast iron sand is often used instead of steel shot when the abrasive cannot be recycled at all. In situations where abrasive recycling is relatively easy, cast iron sand can be recycled 50 times and is often used instead of other economic abrasives such as copper ore sand. Due to the high density of JZRTM, it can also be used as ballast for ships or for shielding in high radiation fields.

Applicable industrial scope: automotive industry, sandblasting/painting companies, container manufacturing/repair, casting/die casting, ocean-going ship repair, OEM distributors, oil and gas pipelines; plant maintenance and steel manufacturing.

Applicable process scope: sandblasting cleaning before steel painting, electroplating or coating; casting sand cleaning; cleaning before mold repair; fine surface constant effect treatment; deep treatment of metal workpieces before galvanizing or enamelling.