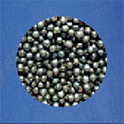

Plastic sand is a man-made sand material used in a controlled, gentle, non-abrasive operating environment without any damage or abrasion to the workpiece. Plastic sand has a low hardness and special specific gravity, suitable for some sensitive operations. There are six specifications of products, each with its own characteristics, which can be applied to any process requirements. Plastic sand is suitable for both dry and wet pressure sandblasting equipment, and can be effectively used at very low pressures to ensure that no damage is caused to the workpiece being blasted. When using equipment with shot recovery and re-sorting functions, the high durability and irregular shape of plastic sand can ensure both high productivity and long life of the shot. Workpieces that are often cleaned with solvents/chemical reagents in traditional processes can usually be shot blasted with plastic sand. Chemical methods endanger the health of operators, require costs for sewage treatment, and environmental problems are often continuous. Using plastic sand for shot blasting is a safe, economical and green method. Plastic sand does not contain active silicon. In addition, chemical methods are less flexible, and the workpiece is immersed in the treatment liquid as a whole, which often causes damage to the substrate or residue of the treated material. Using plastic sand for shot blasting can solve this problem because the shot only hits the part that needs to be removed. Applicable industrial scope: aviation industry, automobile industry, consumer goods manufacturing industry, foundry industry, semiconductor industry. Applicable process scope: deburring of fine computer parts; depainting of the surface of vulnerable substrates, such as aluminum parts, synthetic materials, glass fiber, wood, etc.; removal of mold residues.