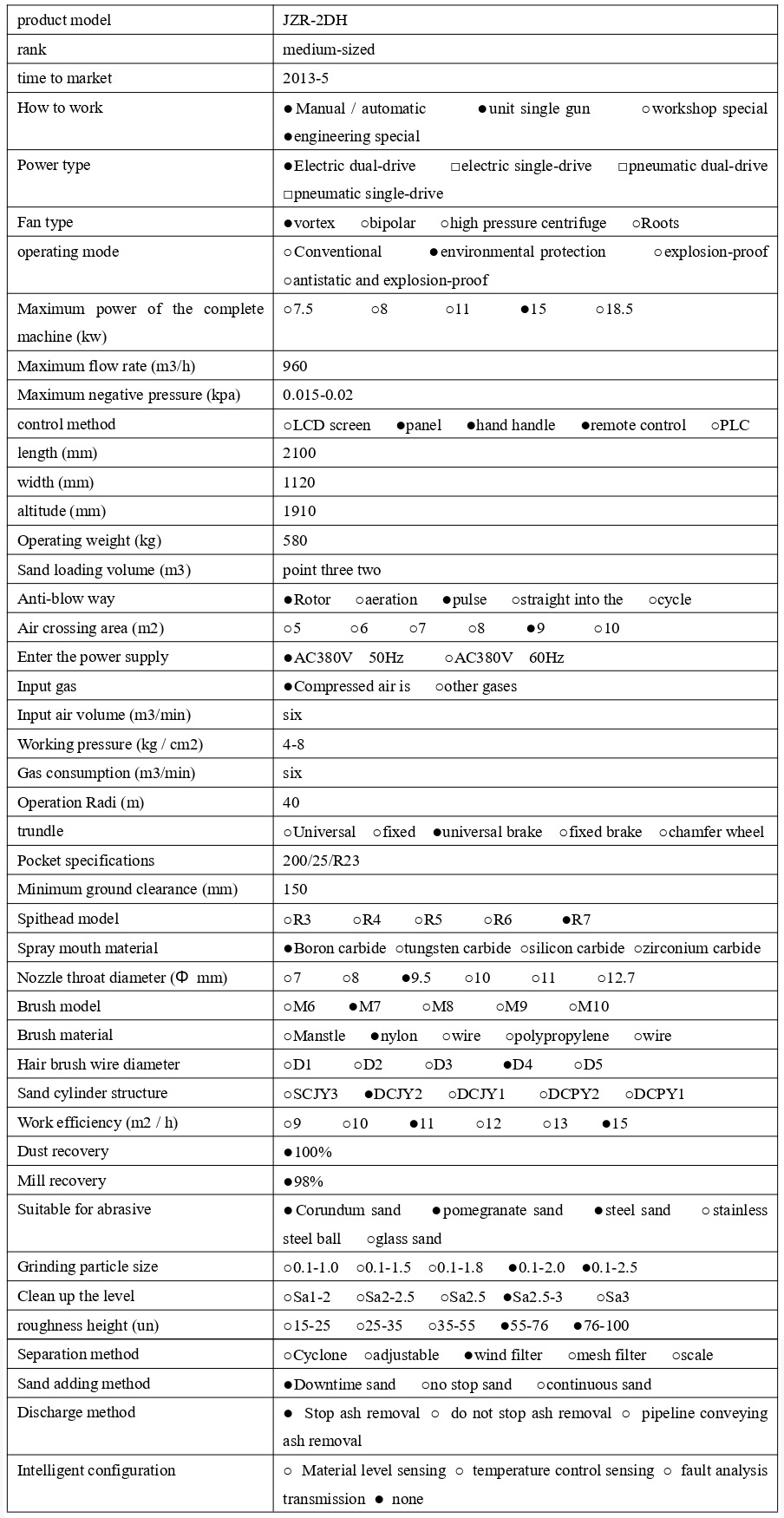

The JZR-2DH environmentally friendly sandblasting machine is specially designed and manufactured for environmentally friendly sandblasting of ship hulls, large oil storage tanks, viaducts, large steel plates and steel components. It is convenient for lifting and transfer, and its dust-free and pollution-free operation ensures that the environmental protection standards are met on site. The excellent surface treatment ability can easily reach the highest level Sa3 in the cleaning level, and the excellent recovery ability can easily recover rust, oxide scale, paint skin, dust, etc. within a 40-meter operating range. For example: surface treatment of oxide scale on steel components, cleaning and rust removal in dock warehouses, bridge anti-corrosion, water conservancy engineering gates, mining, petroleum, chemical industry, metallurgy, port machinery, and vehicle manufacturing fields. The equipment is suitable for light abrasives such as corundum sand and pomegranate sand. After optimization, steel sand can be used. When performing remote or high-altitude long-distance environmentally friendly sandblasting operations on site, it is an ideal equipment choice for cleaning and rust removal, paint removal, and dirt removal on large workpieces and metal structures before coating. The sandblasting operation radius of this equipment is second only to JZR-LZ600.